Structural Steel Detailing Services

Accurate, Buildable Drawings. Delivered with Consistency.

Compass Engineering Inc. provides structural steel detailing services for fabricators across the U.S. We support fabrication and field installation with clear, accurate documentation that meets the standards of commercial, industrial, and institutional projects.

We specialize in working directly with structural steel fabricators, offering flexible detailing solutions that adapt to your workflow. Whether you’re delivering on fast-track builds or complex, multi-phase projects, we offer the detailing support you need to meet deadlines without compromising precision.

Our Steel Detailing Services

We provide a full range of detailing services that cover every critical stage of steel construction documentation. From connection design to BIM coordination, our services are built to reduce fabrication errors, prevent job site delays, and improve material tracking and reporting.

Our engineers and detailers use a combination of industry-leading software, shop-aware modeling practices, and project-driven standards to deliver clear, code-compliant drawings you can trust.

Structural Steel Shop Drawings

Our shop drawings are fabrication-ready and developed to meet your internal shop standards. We include all necessary dimensions, weld symbols, part labeling, bolt sizes, and fit-up instructions. These drawings help your team stay productive and reduce time lost to clarification.

We tailor our deliverables to fit your project’s size and complexity, whether it’s a standalone stair tower or a full structural frame.

Miscellaneous Steel Detailing

In addition to primary structural framing, we detail a wide variety of miscellaneous steel components, including stairs, ladders, railings, embeds, canopies, bollards, and other architectural or functional steel features.

These elements require the same level of clarity and precision as structural members, and we ensure they are modeled and documented for safe, efficient fabrication and installation.

Erection Drawings

Erection drawings are produced to guide accurate field installation. We identify piece marks, provide location references, and supply bracing and sequencing logic that field crews rely on. These documents are designed for readability and clarity under real-world job site conditions.

Connection Design Services

Compass Engineering provides both connection detailing and full engineering design of structural steel connections. Our services cover standard and custom connections including shear, moment, braced frame, and axial connections, based on AISC design guides.

Every connection is evaluated for constructability, cost-efficiency, and safety. We also provide calculation packages and stamped documents as needed per jurisdictional requirements.

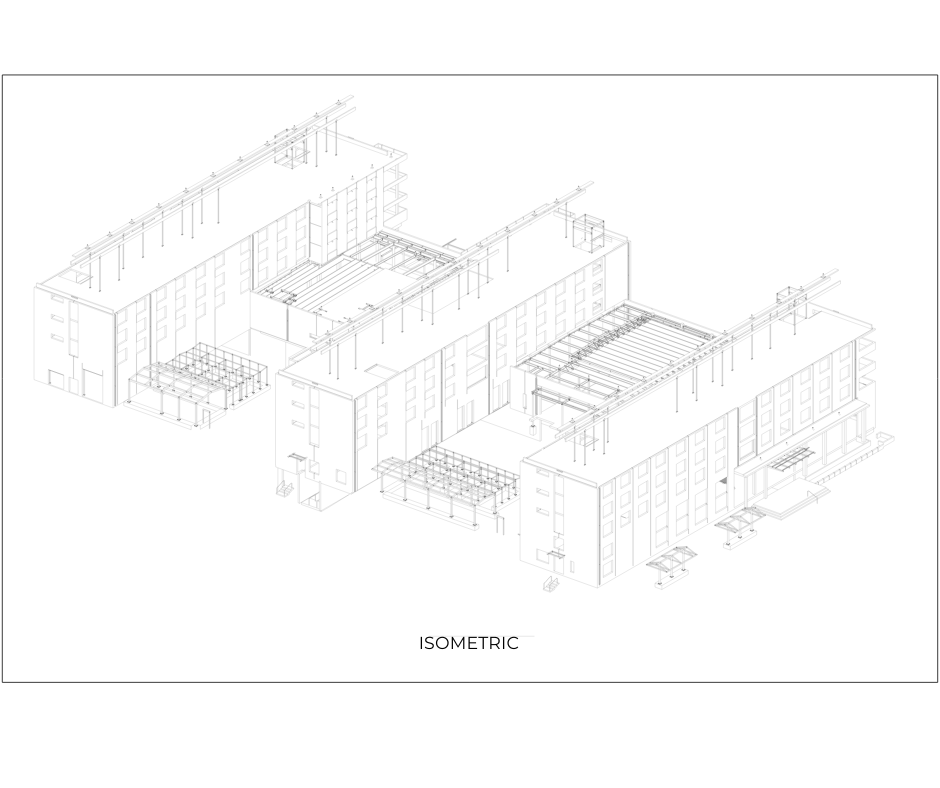

BIM Structural Services

We utilize Tekla Structures to develop 3D BIM models that integrate with the broader design and construction ecosystem. Our models serve as the single source of truth for coordination with joist, deck, concrete, and MEP trades.

This helps catch conflicts early and saves hours during fabrication and field installation. We’re equipped to lead or support clash detection and collaborate in CDE environments like BIM 360 and Trimble Connect.

Reports & Documentation

We generate a wide range of project-specific reports that help fabricators manage materials and workflows:

- Preliminary Advance Bills of Material (ABM)

- Material take-offs

- Field and shop bolt summaries

- Sequencing and erection plans

- Part lists and CNC data exports

- Shear stud and anchor bolt lists

- Custom reports for ERP systems like FabTrol or STRUMIS

All reporting is tailored to match your internal systems and preferred file formats.

Industries We Serve

- Commercial buildings and infrastructure

- Petrochemical and energy facilities

- Heavy and light industrial plants

- Education campuses

- Custom residential and multi-family structures

- Municipal and government projects

- Public and private institutional buildings

- Hospitals and healthcare facilities

- Athletic complexes and sports venues

- Integrated design-build projects across sectors

We specialize in detailing for fabricators, not general contractors.

We speak your language and understand shop workflows.

We deliver consistent results, clear drawings, and real coordination.

We build working relationships that support repeat work and growth.

Why Choose Compass Engineering

Our approach is built around accuracy and consistency. We review every detail, communicate clearly, and deliver models and drawings that align with your fabrication standards.

FAQ

Frequently Asked Questions

Structural steel detailing is the process of creating detailed drawings and models that guide the fabrication and erection of structural steel. These drawings include dimensions, materials, weld details, and bolt information used by steel fabricators and installers.

Yes. We generate 2D shop drawings and 3D Tekla models. The combination ensures your fabrication shop and field crews get accurate, coordinated documentation.

We use Tekla Structures for 3D modeling, and integrate with platforms like AutoCAD, BIM 360, and Trimble Connect for collaboration.

Absolutely. We tailor each project to your fabricator standards and file format preferences, whether it’s for ABMs, CNC data, or FabTrol/STRUMIS integration.

Yes. All deliverables follow relevant AISC codes and OSHA guidelines where applicable, especially for connection design and safety-related aspects.

Lead time depends on the project’s scope, but we’re transparent about timelines and can handle fast-track schedules when needed.

Yes. We work with licensed engineers to provide stamped calculation packages as required by the project or jurisdiction.

Yes. We keep communication open throughout the process to ensure revisions and RFIs are handled efficiently.

Reach out through our contact form or by phone. We’ll review your project requirements, provide a detailed quote, and confirm timelines.